Heat stress is a major risk in O&G facilities, but standard cooling is a safety violation. DUBICOOL engineers Explosion-Proof cooling solutions—from adiabatic chillers to spot misting—fully certified for Zone 1 and Zone 2 environments

The Challenge: Heat vs. Safety

The Thermal Risk in Volatile Zones.

In refineries and chemical plants, ambient temperatures often exceed 50°C. This creates a dual threat:

-

⚠️ Equipment Derating: Gas turbines, compressors, and transformers lose efficiency and trip in high heat.

-

👷 Worker Safety: Personnel wearing heavy fire-retardant (FR) PPE face life-threatening heat stress, reducing focus and safety compliance.

-

🚫 The Barrier: You cannot simply use a standard fan or AC. One spark from a non-rated motor could cause a catastrophic event.

The Solution: Certified “Ex” Cooling

Engineered to Suppress Heat, Not Ignite It.

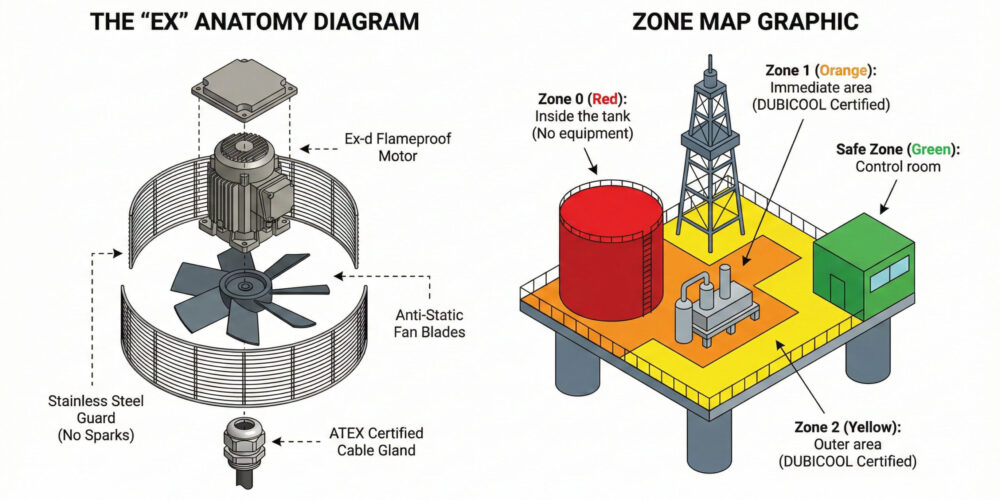

DUBICOOL provides a complete range of hazardous area cooling equipment. Every component in the “Hot Zone” is strictly tested and certified to prevent ignition sources (sparks, hot surfaces, or static).

Technology A: ATEX Misting Fans & Ventilation

-

The Tech: Heavy-duty portable and fixed fans with spark-proof aluminum blades and Ex-d (flameproof) motors.

-

The Application: Spot cooling for maintenance crews during turnarounds or shutdowns on the rig floor.

-

Safety Spec: Zones 1 & 2 (Gas Group IIB/IIC), T3/T4 Temperature Class.

-

Mechanically driven pumps (if required) to remove electrical risks entirely.

Technology B: Adiabatic Pre-Cooling (Safe Area or Ex)

-

The Tech: Retrofitting air-cooled heat exchangers (ACHE) with adiabatic misting to lower process temperatures.

-

The Application: Cooling process gas or oil lines without increasing the footprint.

-

Safety Spec: Anti-static membranes and pneumatically driven pumps (if required) to remove electrical risks entirely.

Applications by Industry

Critical Cooling for Volatile Sectors.

| Sector | Application | DUBICOOL Solution |

| Oil & Gas (Upstream) | Drill floor cooling, Mud pit ventilation. |

Portable Ex Fans & Misting Zones.

|

| Refineries (Downstream) | Cooling process fin-fans, Compressor stations. |

Adiabatic Pre-Cooling for heat exchangers.

|

| Chemical & Petrochem | Storage tank cooling, loading gantries. | Deluge Misting to reduce surface temps. |

| Offshore Marine | Living quarters, machinery spaces. |

Salt-Resistant (316L) Ex Ventilation. |

Technical Trust Signals (The “Ex” Badge)

Compliance You Can Audit.

-

Global Standards: All equipment comes with ATEX (EU) or IECEx (International) certificates traceable to the manufacturer.

-

Spark-Free Materials: We utilize anti-static polymers, 316L Stainless Steel, and Marine Grade Aluminum to prevent friction sparks.

-

Temperature Class (T-Rating): Equipment is rated T3 or T4, ensuring surface temperatures never exceed the auto-ignition point of your specific gas hazard.

Safety is Non-Negotiable. Neither is Cooling.

Maintain production uptime and worker safety in the world’s toughest environments. Trust DUBICOOL for hazardous area climate control.

Contact us now

Misting Skid system