The Challenge: The Cost of Dust

Dust is More Than a Nuisance. It’s a Liability.

In the GCC’s arid climate, airborne particulate matter (PM10 and PM2.5) creates immediate operational risks. Ignoring dust leads to:

-

⚠️ Regulatory Fines: Non-compliance with municipal environmental standards.

-

🫁 Health Hazards: Silica dust exposure causes severe respiratory issues for workforce.

-

⚙️ Equipment Failure: abrasive dust destroys engines, filters, and bearings, increasing maintenance costs.

-

🛑 Downtime: Poor visibility and complaints from neighbors can force site shutdowns.

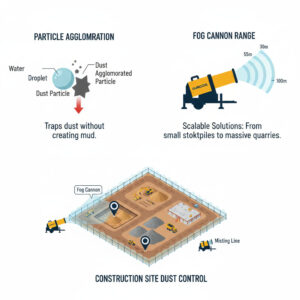

Solution A: Heavy-Duty Fog Cannons

Mobile Power for Open Areas.

Intro Copy: When you need to suppress dust over large distances—such as demolition zones, stockpiles, or open quarries—DUBICOOL Fog Cannons are the industry standard.

-

The Technology: Powerful turbines throw a fine mist (10–150 microns) over long ranges (30m to 100m+).

-

How It Works: The mist droplets bind with dust particles in the air, increasing their weight and forcing them to fall to the ground instantly.

-

Key Features:

-

360° Rotation: Automatic oscillation covers wide areas.

-

Mobile Chassis: Trailer-mounted options for easy relocation across the site.

-

Water Efficiency: Consumes 80% less water than traditional hose-down methods.

-

5. Solution B: High-Pressure Misting Lines

Precision Control for Process Points.

For targeted suppression at specific emission points—like conveyor belts, crushers, or site perimeters—we deploy fixed high-pressure misting networks.

-

The Technology: Stainless steel nozzle lines operating at 1000 PSI create a “curtain” of micro-fog.

-

Applications:

-

Crusher Hoppers: Surrounds the intake to trap dust before it escapes.

-

Conveyor Transfer Points: Knocks down dust where material drops.

-

Site Perimeters: Creates a “Virtual Wall” to prevent dust from drifting to neighboring properties.

-